|

|

| 35 OVER YEARS INDUSTRY EXPERIENCE | |

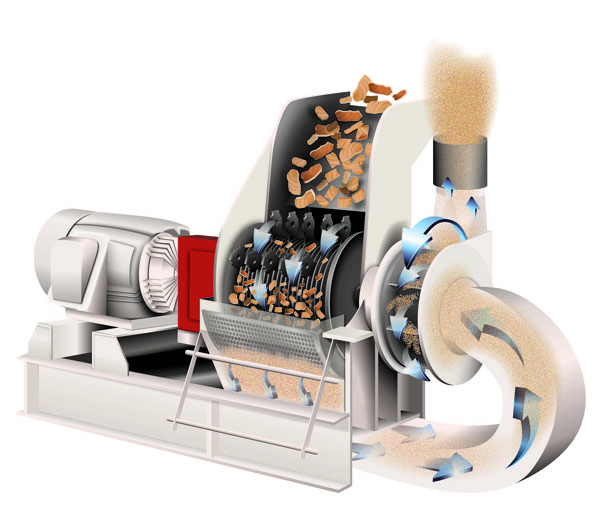

DESIGN BREAKTHROUGH FOR A SUPERIOR GRIND

A unique, horizontal-fed trim scrap grinder that costs less, saves power

and provides a superior, virtually splinter free grind for profitable re-sale.

Build with years of years of hammer mill experience, so you get more out of

it. It's compact, rugged and powerful...and most important, economical to own

and operate.

VERSATILE FOR A VARIETY OF APPLICATIONS

Ideal for sawmills, furniture plants and other woodworking operations which

produce large amounts of trim scrap. It handles a wide variety of wood scrap

- in sizes from 4/4x4x16 feet up to 8/4x12x2 feet - and performs many of the

same functions as wood hogs...at a small fraction of their cost.

COSTS LESS, SAVES POWER

Delivers substantial, ongoing savings in operating costs. It offers a lower

initial cost than competitive models and requires only 75 to 250 horsepower

to grind up to 6 tons per hour. That means power consumption is lower without

compromising high throughput.

SELF-FEEDING FOR FAST, EFFICIENT OPERATION

Wood trim scrap is fed horizontally into the mouth of the grinder, below the

centerline. And because of the unique shape of the hammers - a Schutte exclusive

- the material feeds itself, once inserted. No force is needed and no power

rolls are required, as with other equipment. The self-feeding action is fast

and positive for maximum efficiency.

A MORE UNIFORM GRIND WITH AVAILABLE PARTICLE SIZE CONTROL

Features a range of screen/grates from 3/4" to 2" that produce a uniform product for profitable resale as a superior animal bedding or for mulch, boiler fuel and other applications. The screen/grate is easily removed for cleaning or replacement. If a virtually splinter-free, uniform grind is required, a new louvered bottom grate system of particle size control is available.

EASY ACCESS FOR MAINTENANCE

Hinged drop~down cover permits complete access to hammers and bed knife for easy serviceability and maintenance. The cover drops down without disturbing the infeed throat.

QUALITY FEATURES FOR RUGGED RELIABILITY