|

|

| 35 OVER YEARS INDUSTRY EXPERIENCE | |

Rictec Pte Ltd supply a wide range of wear resistant components for the harsh abrasive conditions encountered in brick and clay based manufacturing environments.

These include:

Wear Resistant Core Buttons

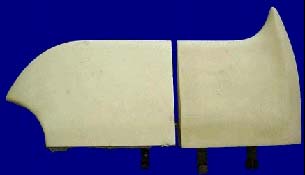

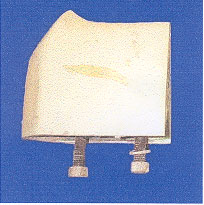

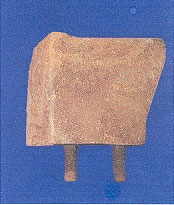

Wear Resistant Ceramic Pug Knives & Paddles

99.8% Alumina Ceramic Pug Knife At 0 Hour |

Original Steel 90 Pug Knife At 0 Hour |

99.8% Alumina Ceramic Pub Knife After 1640 Hours |

Original Steel 90 Pug Knife After 450 hours |

Wear Resistant Scalper Blades

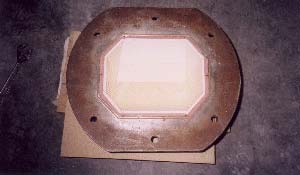

Wear Resistant Die Base

Wear Resistant Bridge Sleeves

Wear Resistant Gouging/Arris Tips

Wear Resistant Die Box/Shaper

Wear Resistant SiC Burner Nozzle

Wear Resistant Arris Wheels

Wear Resistant Bridge Saddle Caps

Wear Resistant Augers

The ceramics in these applications are generally produced from a high purity (99.8%), high density alumina. The components are manufactured by using slip casting or pressing and a high temperature firing process.

These ceramic products offer significant advantages over steel alternatives, such as: